Dynamic Sealing

Seals for rotating shafts.

Over 2000 parts and the constant development of materials and shapes to meet the requirements of the industrial market.

Showing all 8 results

The efficiency of the ridge increases with its size.

Download PDF catalog

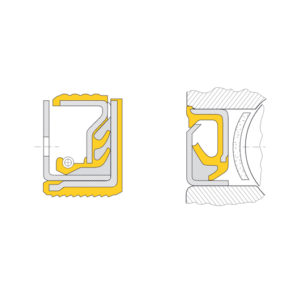

A moulded lip guarantees a better geometrical fit of the sealing lip by eliminating the machining tolerances on:

– the lip angle on the fluid side,

– the distance between the edge of the lip and the axis of the spring,

– the length of the lip (i.e. the distance between the fixing rim and the sealing edge).

Download PDF catalog

The mini-lip has many advantages:

– Reduced dimensions

The decrease in height and the difference between the internal and external diameters allow type IE seals to be used for applications where only type IO used to be possible. The reduced dimensions also mean less weight.

– Less energy loss due to friction

The radial load is smaller, which leads to a decrease of about 30% of the friction torque, which results in:

– a gain in power for the prime mover.

– less heating.

– Increased life

The decrease in heating due to friction results in a lower temperature, which:

– improves the life of the elastomer.

– slow carbonisation, which causes leaks by producing irregularities and stiffening the lip.

Download PDF catalog

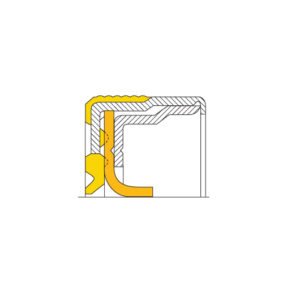

This type of seal has its own friction track.

Its main advantages are:

-reduces the need to grind the shaft,

-treatment of only one part,

-no shaft wear,

– protection of the lip in storage and handling,

– in a bearing, it can serve as a supporting element until it is fitted in the unit.

Download PDF catalog

Teflon has the following advantages:

– a very low coefficient of friction.

– resistance to aggressive products.

Download PDF catalog

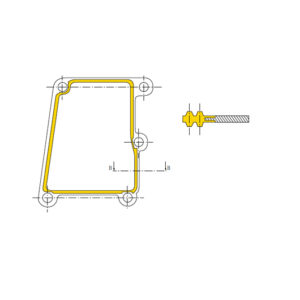

Instead of the metal plate, Paulstra offers a rubberised cover which has the following advantages:

– only a simple shape needs to be machined in the crankcase.

– only one part needs to be fitted to ensure the closure of the crankcase with a perfect seal.

Download PDF catalog

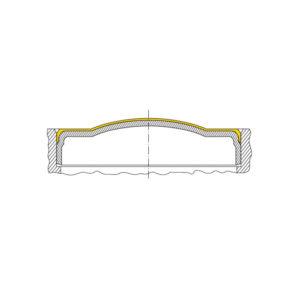

The seal is assured by a beading of elastomer fitted to the inside or the outside of the sheet. The shape of the beading and its attachment to the sheet are designed in such a way that the compression of the elastomer absorbs the faults in the flatness and deformation due to expansion while remaining within acceptable stress constraints.

Download PDF catalog

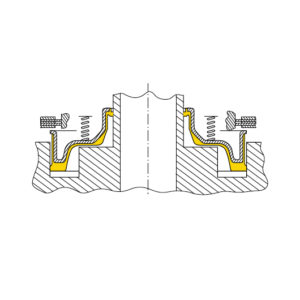

In an automatic gearbox, the setting in motion and the changing of gears are done by clutches on which pistons, moved by oil pressure, act.

Up to the present, these pistons were in moulded aluminium alloy or steel. The sealing for aluminium pistons was done by elastomer seals of various shapes fitted into the grooves or, for steel pistons, kept in position by outer rings.